Connectivity

With a special focus on automation components with high protection ratings of IP67 and higher, Lebenco’s Partner Lutronic is an experienced solution provider for customer-specific assemblies. Not only in large quantities – we are also happy to realize small quantities for you.

All products listed below are examples of customized designs that illustrate the manufacturing capabilities of Lutronic’s factory in Dongguan, China. The items with their unique design are shown with the permission of our customers.

Mechanical Engineering

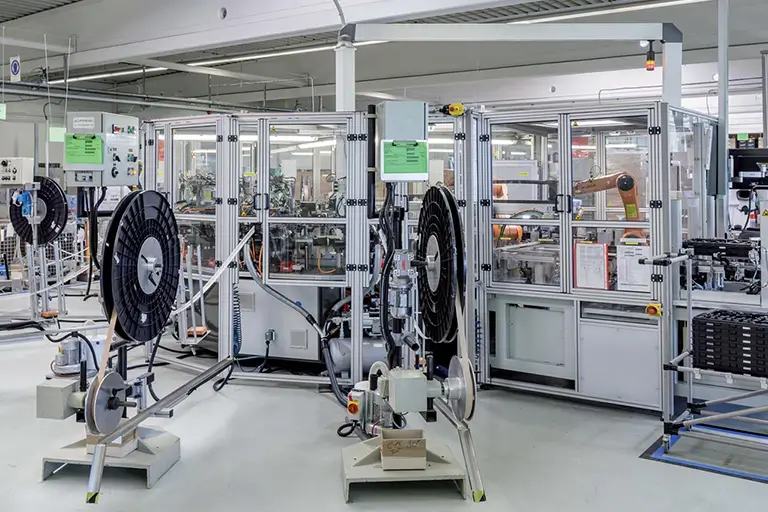

In addition to its positioning as a specialist in connectivity, Lebenco’s Partner Lutronic has taken an even deeper step into the automation industry with its second business unit, mechanical engineering: Lebenco’s Partner Lutronic has integrated special-purpose mechanical engineering into its sales program according to your process requirements in automation.

Developed and manufactured by Lumberg Group´s mechanical engineering in the Cloppenburg factory (Lower Saxony), Lebenco’s Partner Lutronic handles the exclusive sales of this compressed know-how from 175 specialists, which until recently has been dedicated exclusively to Lumberg’s own volume production of connectors and mechatronic components. The experts from the fields of mechanical engineering, software programming and inline test systems create sophisticated solutions for your fully automatic assembly technology or even complete production lines.

Lebenco’s Partner Lutronic is broadly positioned in the field of individualized feeding systems: From spiral and linear vibratory feeders to drum and centrifugal feeders, bulk hopper conveyors as well as reels with a focus on precision and high-speed and, of course, the associated conveyor belts for the transport routes. A highlight of the spiral vibratory feeders, for example, is the knowledge of how to cut the webs in the plastic hopper in order to achieve optimum performance.